The Zero Point System

We make over 100 machined part numbers on 5 axis machines for Trinity AX systems, the majority are machined in two operations, using dovetail fixtures and self-centering vises, we make a high mix of parts in low quantities:

The Dovetail fixture: Raw material is prepped with a dovetail profile, allowing it to be clamped in a dovetail vise. The dovetail vise sits underneath the workpiece allowing unrestricted access to 5 sides of a six-sided cube. Since all raw stock is prepped for either a 1.5” or 3” dovetail, setup time is minimized, and five sides of the part can be machined in one workholding instance. We often run three- or four-part numbers at a time in our system.

Under this scenario, approximately 85% of the part is machined in the first operation on dovetail fixtures that are all the same. This is ideal for lights out production. We load up 15 or 20 pieces of raw material into the dovetail fixtures and the Trinity AX system keeps the CNC machine running throughout the night.

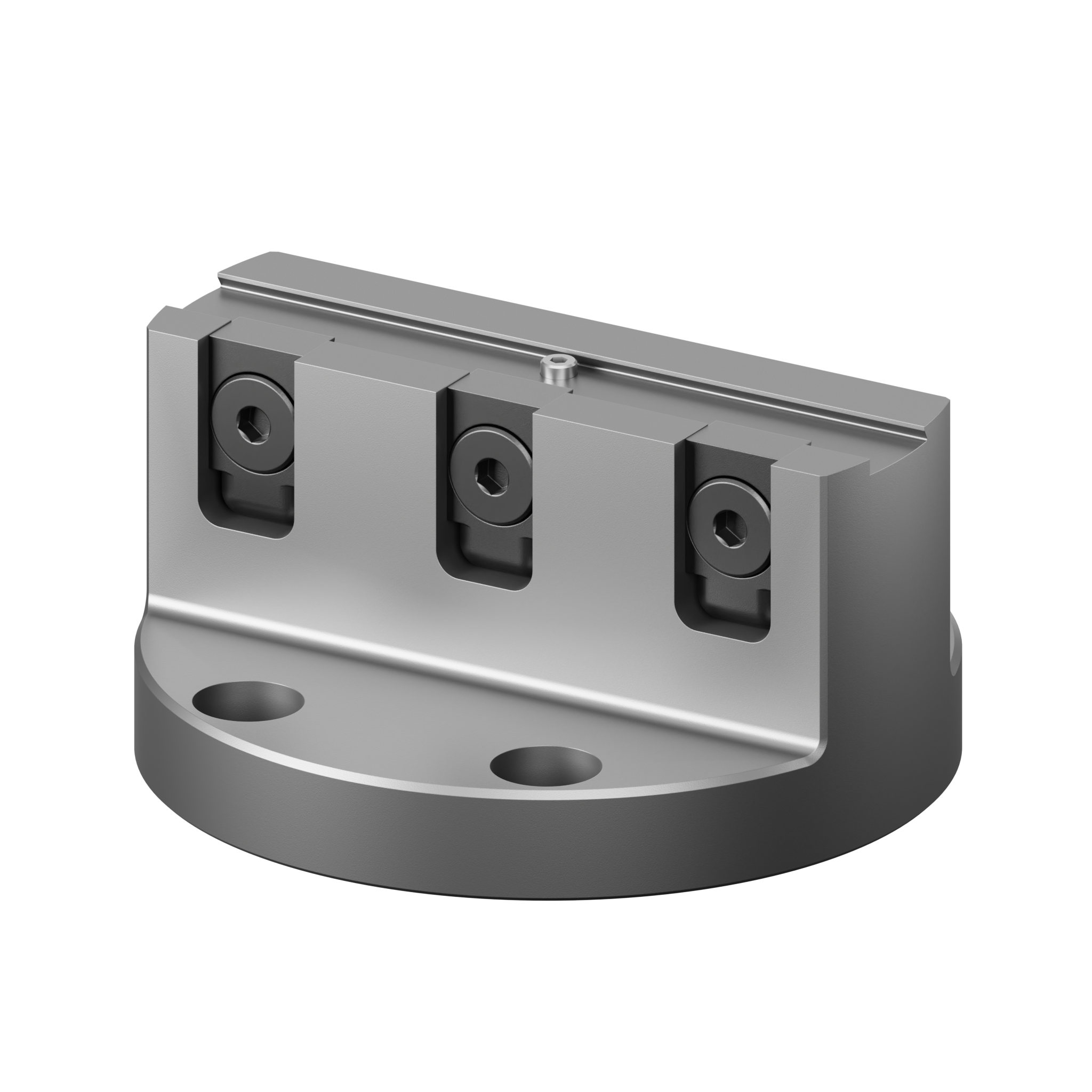

The self-centering vise: The last operation is performed in a self-centering vise so that the workpiece in both operations is always on the center of the pallet. We machine a nest into a set of precision located aluminum soft jaws. Those soft jaws are then stored for future use when the part repeats.

This operation is typically 15% of the part runtime since it is only one side of the part. Additionally, we do not typically make more than two sets of soft jaws for a part number unless we have an unusually high number of parts to make, so the second operation requires more human intervention and is better suited for the day shift, which is manned by humans. We may use six or 8 self-centering vises in our system so that we can run the second operation on three or four different part numbers.

The dovetail feature is .125” high, allowing for a minimum of wasted material