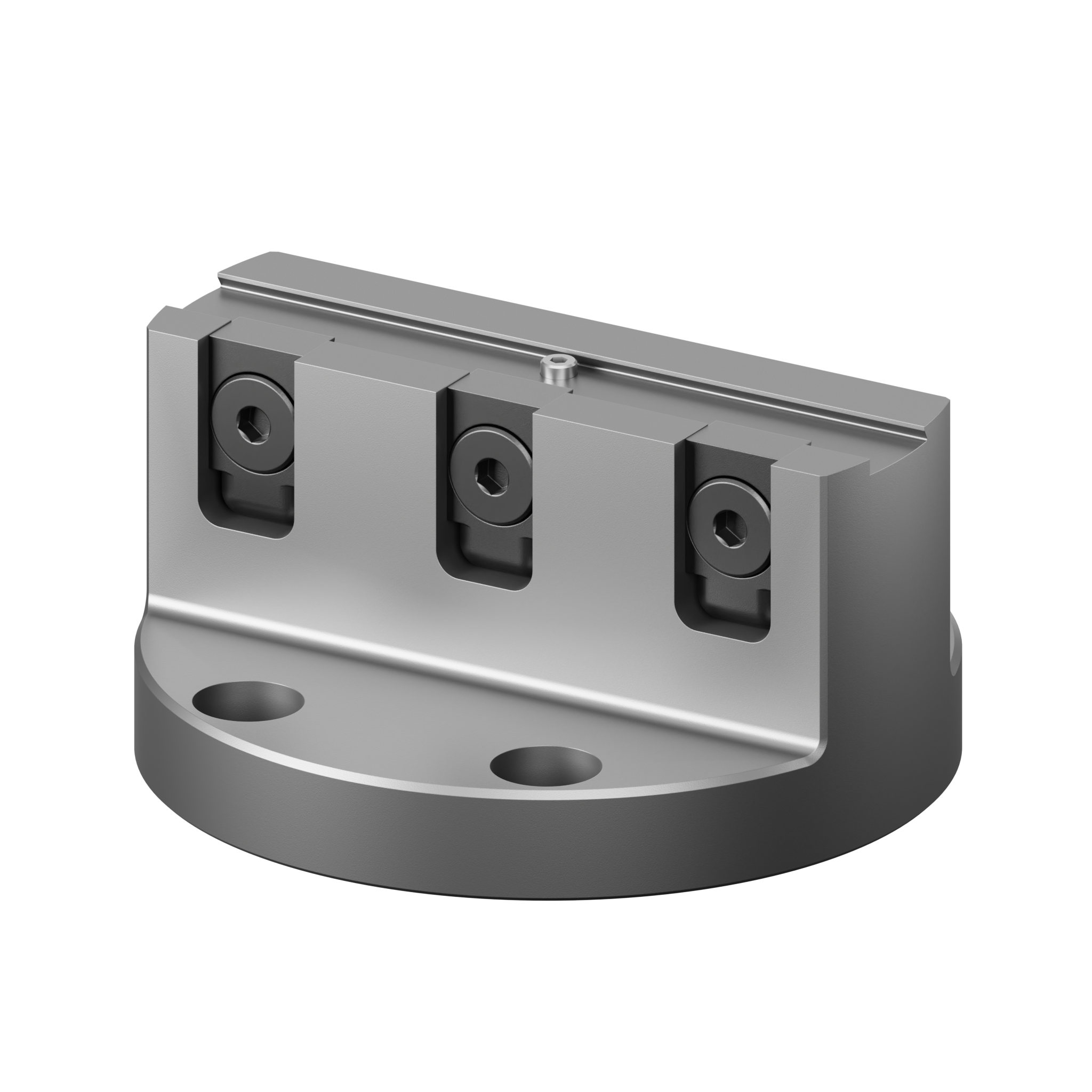

Zero Point System for Trinity Robotics AX

Zero Point System for Trinity Robotics AX

This innovative system is designed to drastically reduce setup times and enhance productivity in the most demanding machine shops.

The Schunk Vero S system features 5-micron repeatability, ensuring the highest levels of precision in your machining processes and providing a stable and secure base for your workholding setups.

Trinity Workholding Pallets: Each Trinity pallet can be machined with fastening and locating features to allow for on-demand workholding changeovers, tailored to your specific machining needs.

Seamless Operation: The Vero S receiver operates pneumatically, featuring an air open, spring closed mechanism. This design ensures that, even in the event of air pressure loss, your pallet remains securely clamped within the receiver.

User-Friendly Interface: Operators clamp and unclamp the pallet using a standard shop air gun (supplied with system). This intuitive approach allows for quick and easy pallet removal or replacement, minimizing downtime and enhancing productivity.

Embrace the future of workholding technology and take the first step towards a more productive, and precise machining environment.